WATER JET CUTTING TECHNOLOGY

Water jet is a cutting process in which the cutter is commonly connected to a high-pressure water pump where the water or water-abrasive mixture is ejected sensitively from the nozzle, cutting through the material by spraying it with the jet of high-speed (800 m/s) water.

The ability to cut material with minimizing the effect of the heat as there is no "heat-affected zone", allows metals to be cut without harming and changing Intrinsic Features.

Hard metals such as titanium, tungsten alloys, stainless steel and carbon steels.

Soft metals such as aluminum, copper, brass, zinc and lead.

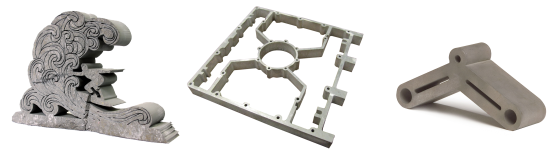

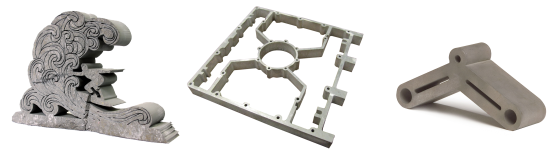

Materials for construction and decoration industry such as granite, marble, ceramic, glass laminated glass and wood.

Carbon, Kevlar, composites, paper, cardboard, learther, textile, products, gasket materials, Plexiglas, polyester, polyethylene sheets, fiber, plastic and rubber derivatives can be cut with water jet.

Water Jet cutting technology is a method that can cut of all materials on earth from thickness 0.1 mm to 160mm.